Keep up with what’s new.

Connect with us on LinkedIn for news, insights and related topics.

UOP has been providing innovative hydrogen processing solutions for more than 50 years. The first industrial application of Pressure Swing Adsorption (PSA) went on stream in 1966. Today, more than 1,000 Honeywell UOP PSA systems have been designed, fabricated and delivered worldwide, representing about 25 million Nm³/h of pure hydrogen produced.

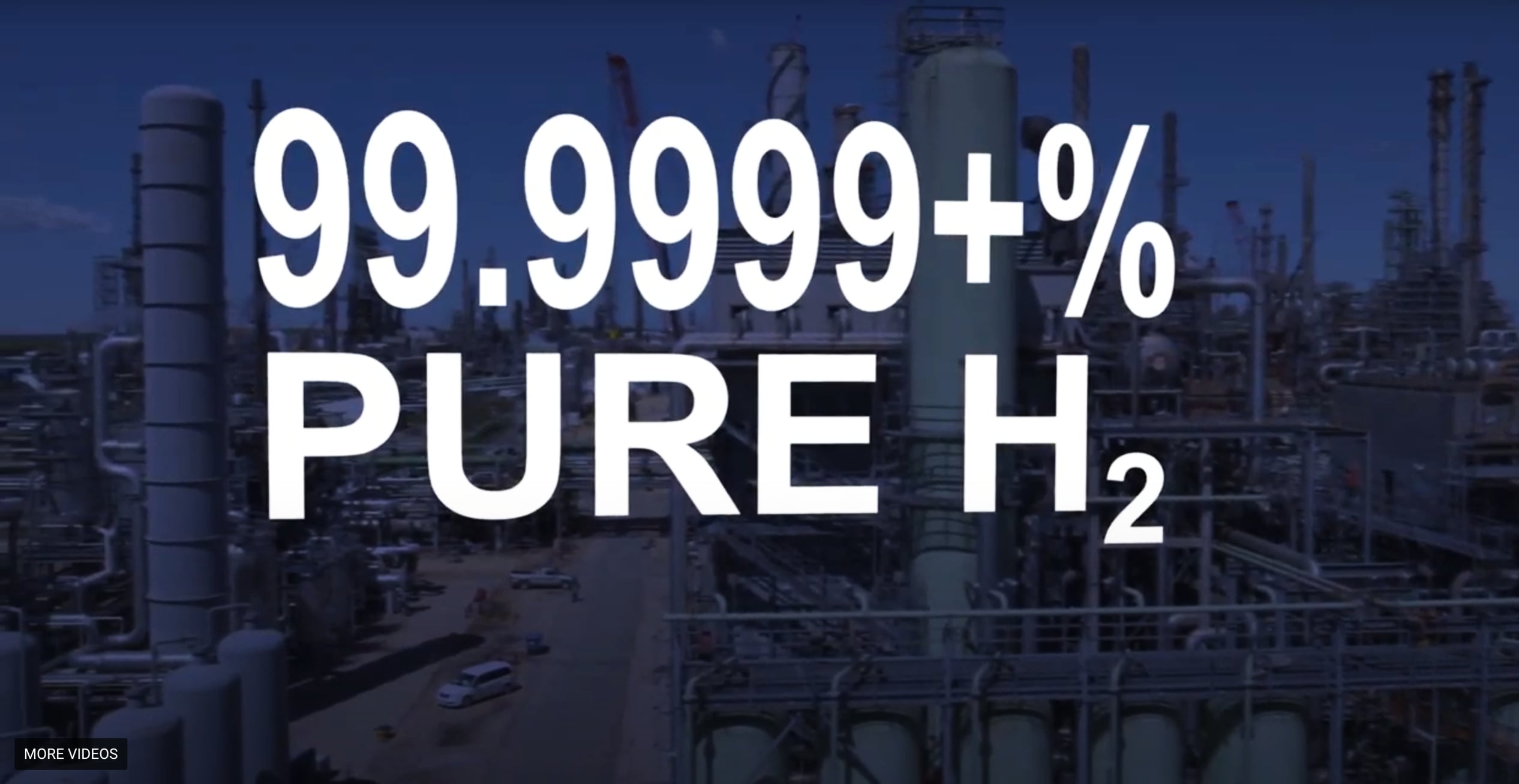

Hydrogen can be produced on purpose or can be a valuable by-product. Regardless of how it’s produced, it must be recovered and purified to be useful in downstream processing. Our hydrogen purification solutions provide targeted hydrogen recovery and high product purity levels.

Technical innovation in adsorbent and membrane chemistry, along with process design and control expertise make UOP the industry’s choice to manage your new installation or revamp – from initial development to commissioning and start-up.

From design and commissioning to operations and optimization, our service solutions are with you every step of the way.

Connect with us on LinkedIn for news, insights and related topics.

Did you know that your internet browser is out of date?

Your browser is out of date, and may not be compatible with our website.

Just click on the icons to download a compatible browser.

By closing this window you acknowledge that your experience on this website may be degraded.